The Australian agricultural industry relies on chemicals such as fertilizers, herbicides, pesticides and insecticides for successful farming. Ensuring precise dosing of these chemicals while minimising direct contact is paramount. Garpen’s precision chemical pumps play a crucial role in meeting environmental and safety regulations, providing safer work environments, and optimising farm yields during seeding season. Using manual pumps may not offer the same level of control and safety.

Garpen supplies top-quality chemical pumps to farms across Australia, enhancing efficiency while reducing risks of spills, chemical exposure, and waste during seeding. Below, we delve into selecting the right pump for your farm’s needs.

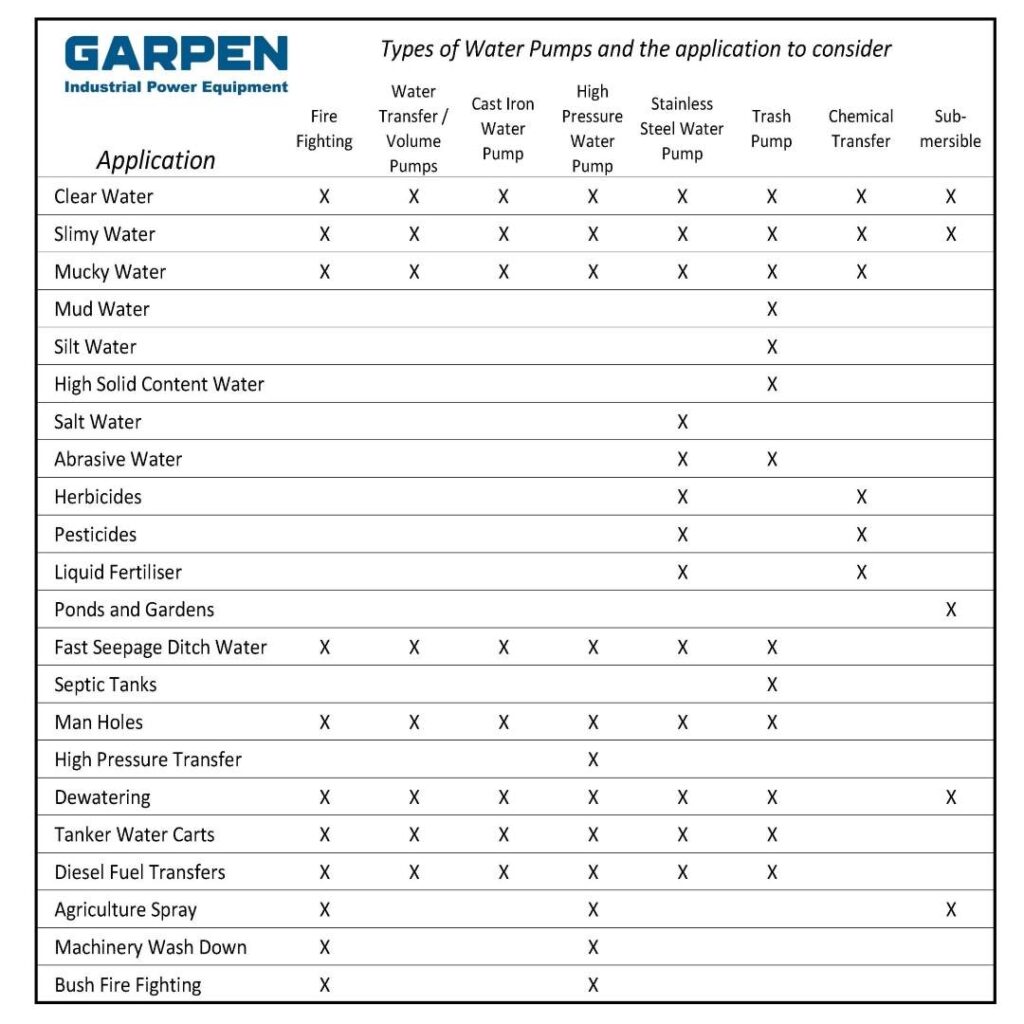

Chemical transfer pumps are used specifically to safely transfer and dispense chemicals or toxic contaminated water.

Chemical Dosing Processes

The complexity of chemical pumps varies based on operational scope and the nature of chemicals involved. Factors such as viscosity and potential reactions are important considerations. Some pumps incorporate separate chemical tanks for precise dosing intervals and quantities to manage these complexities.

While many agricultural chemicals can be safely premixed and run through water pumps designed for chemical handling, discharge and pressure are critical factors affecting uniform distribution. Uneven distribution can lead to varied growth and reduced yields, while excessive water can cause soil erosion and nutrient loss. Manual pumps are not recommended for chemical dispersion.

Benefits of Centrifugal Pumps

Chemicals can accelerate wear and corrosion in pump mechanisms, impacting flow consistency and pressure. Centrifugal pumps, installed above water surfaces, mitigate corrosion issues caused by chemical exposure.

The centrifugal pump is a positive-displacement pump that does not need wall suction near the liquid level. These pumps move liquids and gases by utilizing a motor or engine. Operating with a low head pressure, they are frequently used for high-volume pumping tasks.

The pumps have impeller blades that move fluids by shifting fluid pressures toward the center of rotation and auxiliary equipment like piping support assemblies, valves, and pumps for transferring liquids through pipes. This has a uniform velocity flow that also makes it well-suited for feeder systems in chemical industries.

For most agricultural applications with normal water viscosity, centrifugal pumps are the preferred choice due to their consistent performance.

Optimal Pump Selection

Chemical transfer pumps are used to pump chemical fluids from one location to another. They are specifically designed to handle chemicals and other corrosive or abrasive fluids.

Consulting with pump specialists and irrigation designers is essential for identifying the most suitable pump for your farm. Consider factors such as the types of chemicals used, crop varieties, growth stages, root structures, and soil composition to ensure proper water flow and chemical compatibility.

High quality PA66 plastic pump housing and impeller extends the life of the pump. The Silicon carbide mechanical seals are designed for long and superior abrasion resistance.

GARPEN Pumps are assembled in Australia and are built with time-proven reliable engines.

GARPEN Chemical Transfer Pumps

Discover the perfect chemical pump solution for your farm with Garpen. As one of Australia’s premier suppliers of chemical pumps, fire fighting pumps, transfer pumps, and trash pumps, we assemble all our products locally and back them with a 12-month or 500-hour warranty. Contact our team today to discuss your requirements.